Operational Excellence

Operational Excellence

Maintaining Focus in a Time of Volatility

Overview

What is Operational Excellence?

While many organizations have had great success in improving the efficiency of their manufacturing and assembly processes, there is still a lot of room for improvement in areas like logistics, maintenance, and quality, as well as administrative support activities which must be aligned for efficiency, ideally coordinated with direct functions, and transformed into a continuous improvement process. Reducing and eliminating waste in direct and indirect units improves operational and financial key metrics also sustainability goals have been included to excellence KPIs.

Operational Excellence

Leveraging performance intelligence to increase Agility, Reliability, and Efficiency

The COVID-19 pandemic exacerbated previously unnoticed global supply chain vulnerabilities, resulting in revolutionary upheaval and rapid transition. The pandemic had a substantial impact on the operating operations of manufacturers and processors, driving them to accelerate their transformation journeys in order to adjust in real-time to these rapid market fluctuations and become more productive and operationally robust.

Obtaining operational excellence is now more critical than ever. Companies’ focus has shifted to achieving higher levels of operating performance as competition has intensified and expectations for high performance have risen. As a result, an Operational Excellence program has been implemented by 80-90 percent of Fortune 500 companies.

Manufacturers and processors must continue to speed up their transformations by using performance intelligence in a common link between engineering and operations to improve agility, reliability, and efficiency while also ensuring operational resilience and sustainability.

What to Expect

Between Strategy & Execution that surfaces evidence to Performance Management and Change

Everyone in the organization can use to talk about Operations, objectives and their aspiration.

Our Approach

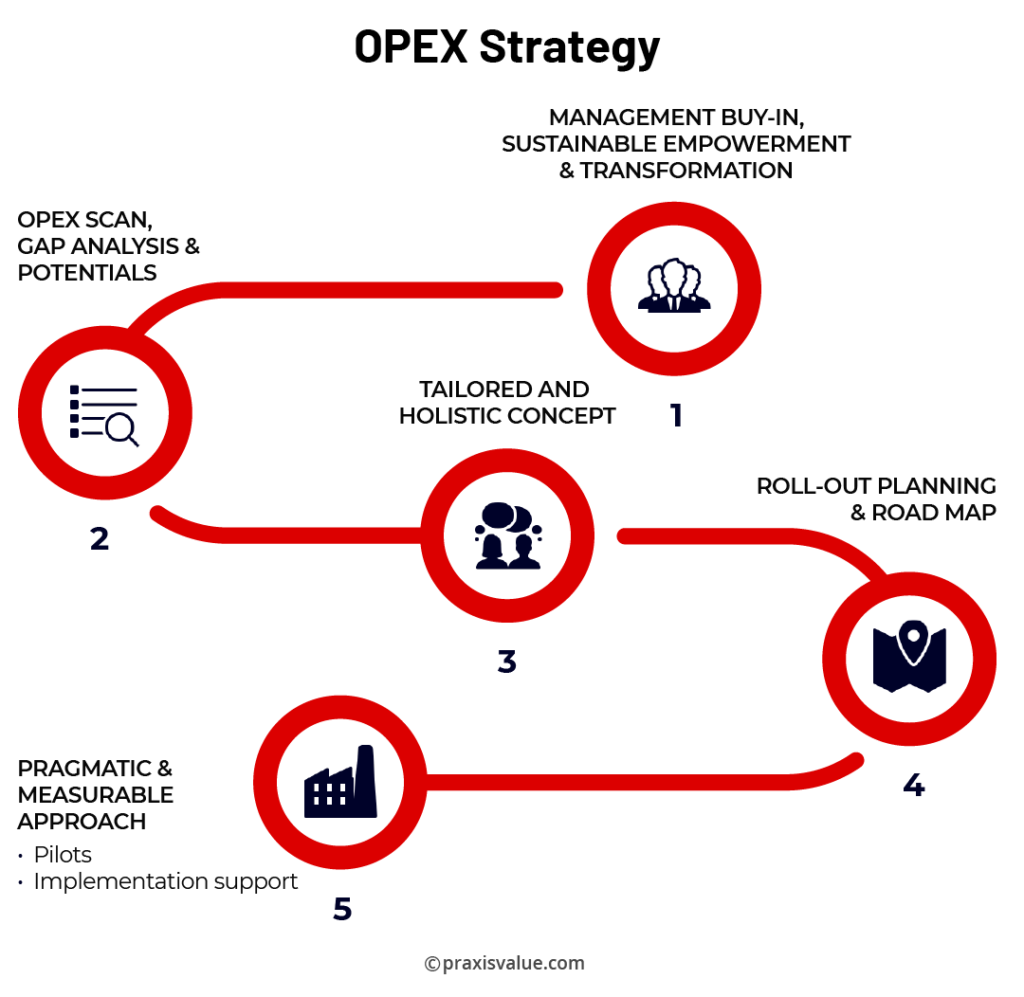

Approach to Operational Excellence: From Potential Analysis to Measurable Results

Praxis Value Management Consulting creates OPEX organizations using a deep methodology and years of project expertise to fit company-specific conditions and structures. We focus on designing an optimal OPEX system and identifying operational potential. The Praxis Value method is made up of five modules: Training & Transformation Management, Gap & Potential Analysis, OPEX System, and Rollout Planning.

The way that businesses operate and the competitive environment in which they operate are both being disrupted on a regular basis. It’s difficult to keep up, therefore your company needs to be adaptable and quick to change, with a culture that recognizes, welcomes, and even encourages business transformation. Praxis Value’s qualified specialists and industry expertise, experience, and ability to assist organizations to identify the path ahead and create a road map that will bring them there profitably and efficiently.

At Praxis Value we leverage facts to make impactful decisions, with the goal of maximizing financial value, and this spirit infuses all we do. Our approach is to capitalize on the potential opportunities, which results in an increase in EBITDA.

Benefits

Improvement

Complexity and Cost

Customer NPS

Client Results - Case Study

Industry – Industrial Engineering

A manufacturing was suffering from slow growth and diminished market share. To remain competitive, it needed to improve its manufacturing facilities to reduce cost and increase capacity. It also need to invest in innovation to remain competitive. Praxis Value Incorporated Lean Six Sigma principles to improve the company’s plant performance, which yielded 15 percent cost savings and increased flexibility.

Business Transformation with Praxis Value

Unlocking Value Fast

By focusing on the key areas for innovation, Capabilities & performance alignment with key enterprise strategies

Sustaining Success

By collaborating with leaders across the company to ensure that operational advantages are sustained over time

Strengthening Capabilities

By offering organizations the digital tools, skills, and expertise they need to tackle the operational challenges