Solution

SMART Factory

SMART Factory

Take processes and organization of the factory - To a new level

Overview

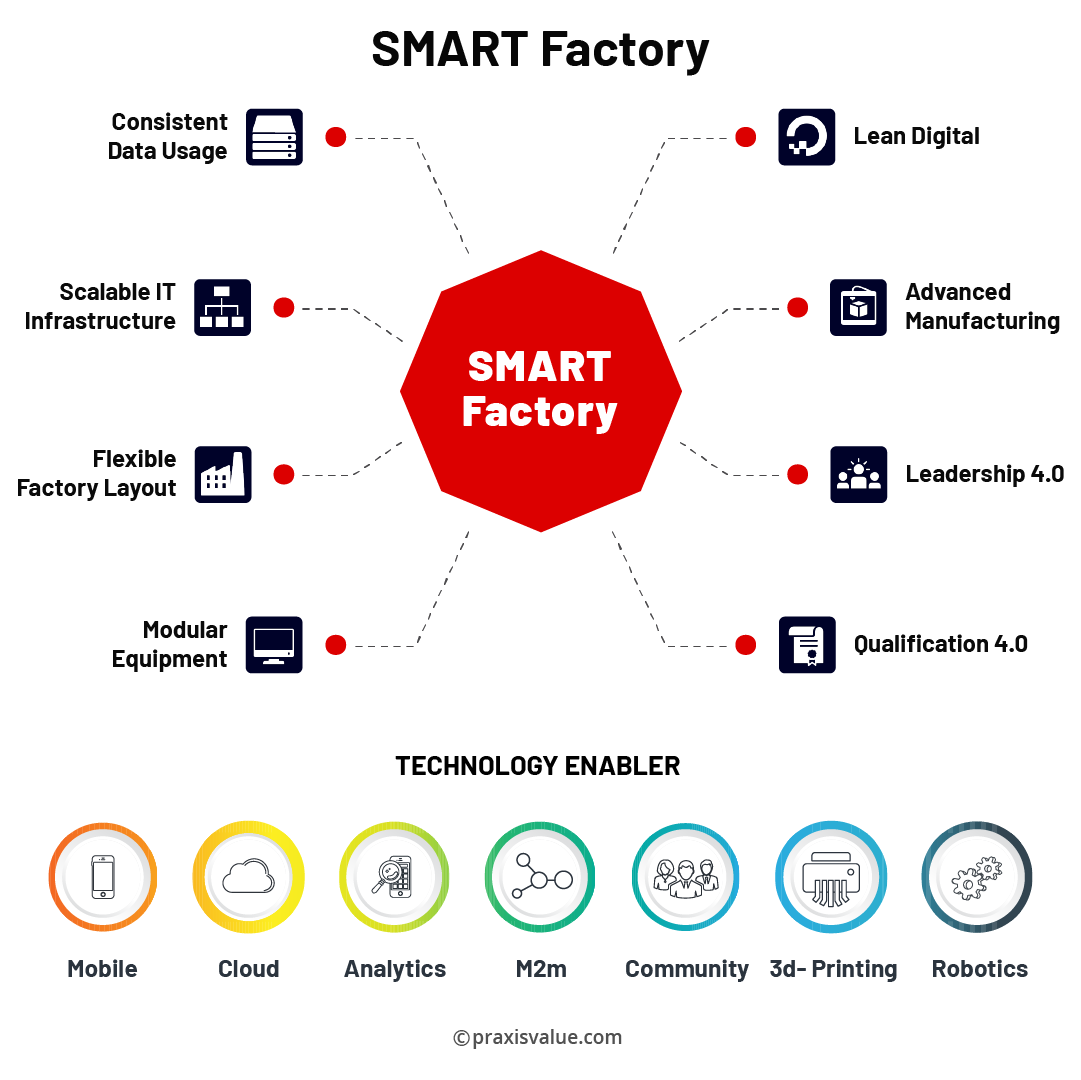

What is SMART factory?

The “closed loop,” data-driven optimization of end-to-end processes is a key feature of a smart factory. At first, advanced analytics are used to help make decisions. However, the ultimate goal is to have “self-optimizing operations,” in which the factory constantly adjusts to changes in demand, supply, and process.

SMART factory

The potential value add from smart factories is bigger than ever

Smart factory investments are rising. The market for MES, ERP, PLM, and other smart factory technologies is expected to be worth $154 billion in 2019. This market is expected to grow at a CAGR of 10% between 2019 and 2024.4. Smart manufacturing platforms are predicted to increase at a 20% CAGR over the next five years, reaching $4.4bn in 2019. 5This growth confirms a 2017 trend we witnessed. Almost 45% of manufacturers had a smart factory program.

One-third of factories have been converted to smart facilities, compared to one-quarter two years ago. In the next five years, they want to build 40% more smart factories and raise yearly investments by 1.7 times. Organizations focus on efficiency by design and closed-loop processes.

This increase is due to smart manufacturing initiatives, businesses’ ambitious planning, and increased expected benefits. These benefits include greater productivity, rapid product-portfolio rotation, and shorter time to market, which will boost market share.

What to Expect

Our Approach

Accelerate and secure Smart Factory Transformation

Smart factories have enormous possibilities, and businesses are already transforming. Scaling these projects is proven to be a major problem for Praxis Value. We established the framework for the major four aspects (Governance, Deployment, Culture & Digital Skills) based on our research and what it reveals about the characteristics of front runners – as well as our experience in advising the businesses and organizations.

At Praxis Value we can determine the most appropriate new technologies to adopt and combine for each industry we work in. We have the capacity to conceptualize and create with our clients, to design, create, and then operate the systems they require. We can reimagine our clients’ business models, increase end-user experiences, and find new revenue streams and cost savings for them. We will speed up the intelligent industrial revolution by fusing these fields of knowledge and international expertise.

At Praxis Value we leverage facts to make impactful decisions, with the goal of maximizing financial value, and this spirit infuses all we do. Our approach is to capitalize on the potential opportunities, which results in an increase in EBITDA.

Benefits

Operational Excellence

Efficiency by Design

Readiness & Cyber Security

Client Results - Case Study

Industry – Industrial Engineering

Our client was facing issues when it came to optimizing a production plant for dashboards: the entire process chain, as well as all risk elements in production and supplier management, had to become more transparent. At the same time, because a sensitive material was being processed, even minor manufacturing errors resulted in complete output rejection; the scrap rate had to be lowered

Industry 4.0 with Praxis Value

Better Productivity

Praxis Value assists industrial firms of all sizes in utilizing smart manufacturing to enhance their operational activities and production.

Improved Workflow

We provide strategies and solutions that enable you to increase productivity and value creation on your projects.

Hidden Insights

Our dedicated team of industry experts will ensure that you get the most out of Industry 4.0, the Internet of Things, and advanced analytics.

Experienced Workforce

Our firm is comprised of seasoned senior analysts from a variety of industries and data scientists skilled in advanced statistical modelling.

What we think

What can we help you achieve?

You are on the way to the easiest business growth ever. Don’t hesitate and reach us today to change the future