Solution

Inventory Cost program

Inventory Cost program

Reduce Inventory now and reduce Cost

Overview

What is Inventory Cost?

Inventory is not free. Storing more stock than your rate base allows, will reduce your profits potential due to regulatory latency and O&M carrying costs. Inventory is no longer regarded as an asset with a reasonable expectation of rate recovery. Both management and utility inspectors are increasingly scrutinizing inventory investments and it must be efficiently managed and budgeted, as the industry is discovering.

The cost of inventory’s carrying cost is the most significant. The average inventory carrying costs, including the weighted average cost of capital, is determined to be in the range of 7%–16%. Taxes and insurance, which are changeable components of the inventory carrying cost, account for a considerable percentage of the inventory value.

Inventory Cost

Many times, manufacturers have a considerable portion of their financial resources invested in their inventories. Studies indicate that inventory, which includes accounts receivable and payable, is projected to be worth $1.1 trillion in cash, which is equivalent to 7% percent of the gross domestic product of the United States.

The good news is that contemporary analytics has the potential to salvage a sizeable portion of the value contained within this money. As a component of Industry 4.0 and the pervasive technologies it entails, manufacturers are beginning to implement distribution centers that are analytics-based, inventive, and data-driven.

Distributors will make use of this technology in order to stop relying on conjecture when attempting to forecast the demand for products and instead integrate information in order to provide accurate projections about the future. They will be able to arrive at economically sound conclusions on their own.

What to Expect

Direct the finances on endeavours & activities that will contribute to business development.

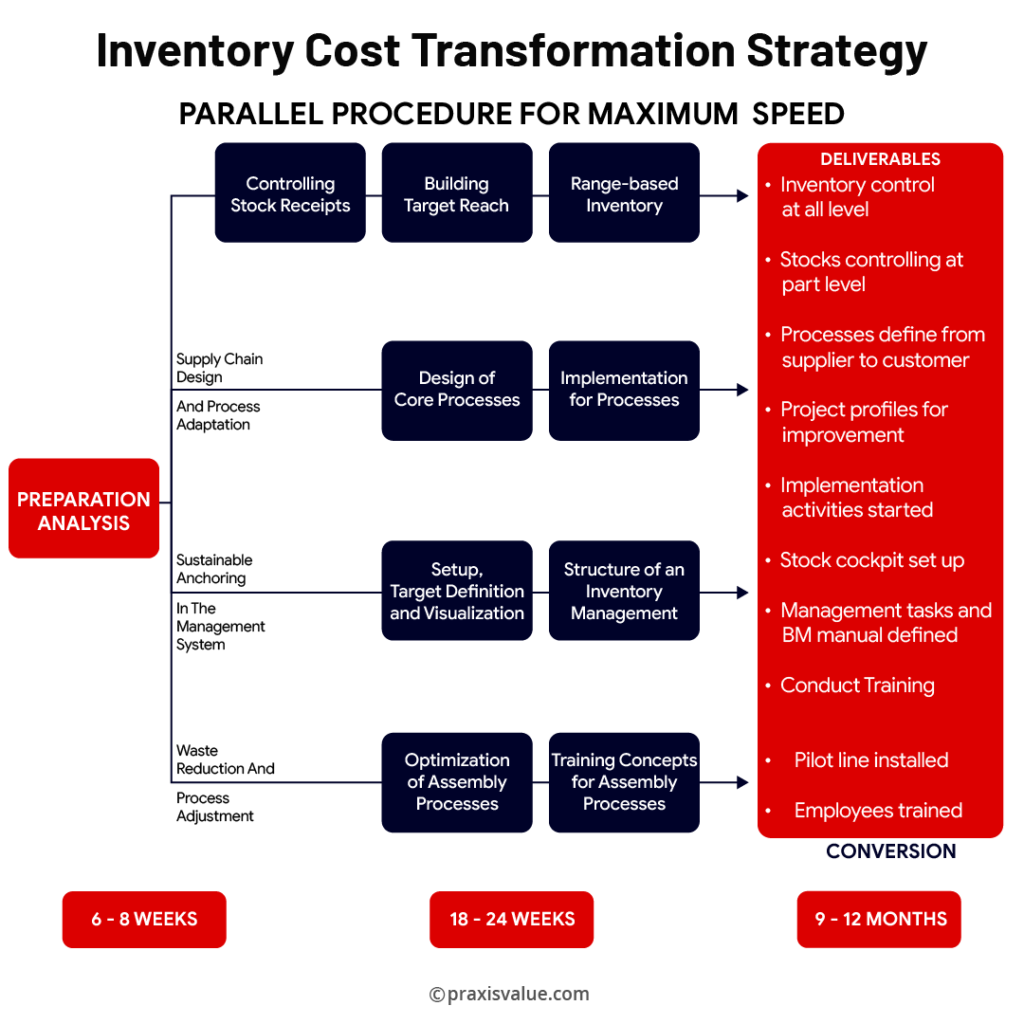

Our Approach

Our program assists businesses in reducing inventory expenses fast and sustainably, freeing up funds for strategic and operational objectives. The answer is a mix of reengineering supply chain operations, using digital planning and control methodologies, improving supplier collaboration, and instilling inventory management expertise in the management team.

Praxis Value Cost Management focuses on enterprise-wide, structural changes that might lead to long-term cost reductions and profit increases. In doing so, we work to assist our clients in creating cost structures that are scalable and profitable to generate profits. Based on our significant experience with cost improvement initiatives across industries, our services typically fall into main transformation strategies to assist firms in addressing their unique cost and strategic concerns.

At Praxis Value we leverage facts to make impactful decisions, with the goal of maximizing financial value, and this spirit infuses all we do. Our approach is to capitalize on the potential opportunity, which results in an increase in EBITDA.

Benefits

Labour Productivity

Return on Investment

Inventory Levels

Client Result - Case Study

Metal Industry - Aluminum Business

Champions never rest on their laurels, but instead focus on the next stage goal. A company with around 5000 people across multiple sites is likewise on the lookout for a “North Star.” It all starts with an operations strategy and the initiatives that follow it, which should be applied at every location to improve efficiency. In addition to the OPEX problems, the corporation reorganized all manufacturing facilities using the “zero-based organization” method in collaboration with Praxis Value…

Cost Reduction with Praxis Value

Unbiased Viewpoint

We leverage facts to make informed & impactful decisions, with the goal of maximizing financial value, and this spirit infuses all we do

Straight to the point

We bring the experience and approach to capitalize on potential opportunity, which often results in a 20–40% increase in EBITDA

Execution & Speed

Because time is the single asset that can never be bought back, we understand the significance of delivering True Value – Rapidly

Innovative toolbox

Our cutting-edge, one-of-a-kind approaches help businesses in accounting for complexity costs and comprehend their true profitability

What we think

What can we help you achieve?

You are on the way to the easiest business growth ever. Don’t hesitate and reach us today to change the future