Solution

Value Based Engineering

Value Based Engineering

Reduce Manufacturing Costs & Shorten Time-to-Market with Design -to-Cost

Overview

What is Value Based Engineering?

Value engineering is used to discover and remove wasteful expenses, enhance functionality, and increase quality. The goal is to improve the value while reducing the cost of conformance to the product’s performance standards.

Value Engineering is a creative, structured initiative aimed at reducing the entire life cycle costs by identifying and implementing methods of reducing capital, personnel, energy, and maintenance expenditures. To determine value creation areas, an investigation is done through a multi-disciplinary group. The study explores various design concepts, materials, and techniques while maintaining the client’s functional and value objectives.

Reduction in unplanned

Machines are stressed in these conditions, and the high preventative and reactive maintenance costs required to keep them functional can be a financial strain. Poor maintenance methods can now lower a plant’s overall productive capability by 5 to 20%. Long and uninterrupted runtimes of highly interconnected assets can be a substantial competitive advantage.

Value Based Engineering

Adopting a value-based attitude and identifying value drivers are just half the battle. Managers must create methods that bring this attitude to life in the company’s everyday operations. Line managers should embrace Value-based thinking as a better approach to make choices. And, for VBM (Value Based Engineering) to be successful, it must eventually engage every business decision-maker.

The implementation of VBE (Value Based Engineering) is governed by four essential management procedures that work together. First, a firm or business unit devises a value-maximising strategy. Second, it converts the strategy into short- and long-term performance goals based on the primary value drivers. Third, it creates action plans and budgets to outline the measures. Finally, it implements performance measurement and reward systems to track employee progress against targets

At the corporate, business-unit, and functional levels, these four processes are intertwined. Strategies and performance objectives must be uniform throughout the organisation if the business accomplishes its value creation goals.

What to Expect

Direct the finances on endeavours & activities that will contribute to business development.

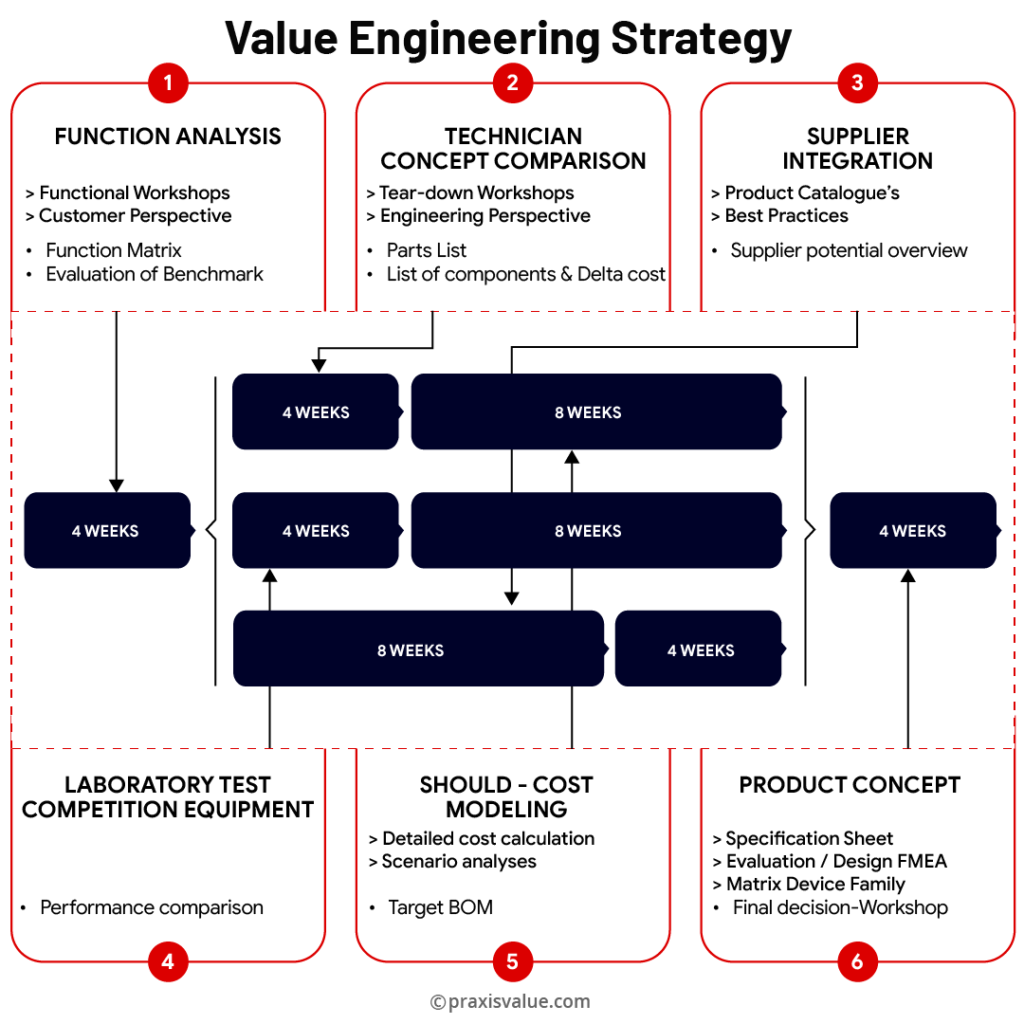

Our Approach

The Value-Based Management team assist you in increasing the profitability of processes, improve customer satisfaction, mitigate risk, and reducing expenses. We make sure that you design cost-effective products in both manufacturing and operational expenditures by using a combination of IT tools, Cost assessments, FMEA, shock & target costing techniques, external benchmarks, and testing.

Praxis Value Cost Management focuses on enterprise-wide, structural changes that might lead to long-term cost reductions and profit increases. In doing so, we work to assist our clients in creating cost structures that are scalable and profitable to generate profits. Based on our significant experience with cost improvement initiatives across industries, our services typically fall into main transformation strategies to assist firms in addressing their unique cost and strategic concerns.

At Praxis Value we leverage facts to make impactful decisions, with the goal of maximizing financial value, and this spirit infuses all we do. Our approach is to capitalize on the potential opportunity, which results in an increase in EBITDA.

Benefits

Manufacturing Efficiency

Time – to – Market

Cost Savings

Client Result - Case Study

Metal Industry - Aluminum Business

Champions never rest on their laurels, but instead focus on the next stage goal. A company with around 5000 people across multiple sites is likewise on the lookout for a “North Star.” It all starts with an operations strategy and the initiatives that follow it, which should be applied at every location to improve efficiency. In addition to the OPEX problems, the corporation reorganized all manufacturing facilities using the “zero-based organization” method in collaboration with Praxis Value…

Cost Reduction with Praxis Value

Unbiased Viewpoint

We leverage facts to make informed & impactful decisions, with the goal of maximizing financial value, and this spirit infuses all we do

Straight to the point

We bring the experience and approach to capitalize on potential opportunity, which often results in a 20–40% increase in EBITDA

Execution & Speed

Because time is the single asset that can never be bought back, we understand the significance of delivering True Value – Rapidly

Innovative toolbox

Our cutting-edge, one-of-a-kind approaches help businesses in accounting for complexity costs and comprehend their true profitability

What we think

What can we help you achieve?

You are on the way to the easiest business growth ever. Don’t hesitate and reach us today to change the future