Solution

Digital Twins

Digital Twins

Process Optimization through Predictive Quality and Predictive Production

Overview

What is Digital Twins?

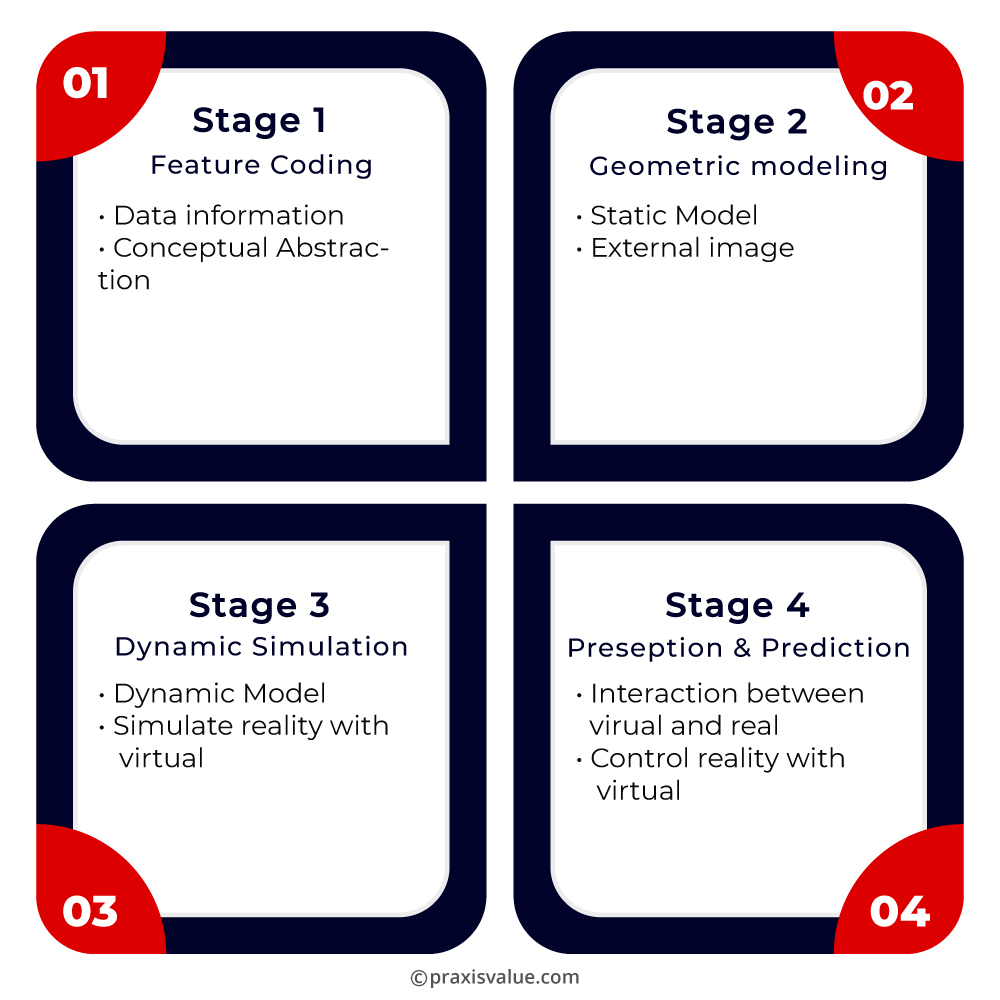

Digital twins are promising Industry 4.0 and IoT applications (IoT). Virtual, dynamic models map a physical object or process in real time, allowing exact predictions regarding performance, weak areas, material fatigue, and other risks. Classical digital twins are developed for cost-intensive, critical, and lasting products, including complicated machines, and provide insights on product optimization and maintenance.

Digital twins for processes (Digital Process Twins) provide evaluations of the complete value-added process or network, utilizing digitization and networking. When the whole value-added cycle is simulated virtually, hidden inefficiencies are found, important production problems are solved quickly, and important structures, processes, and resources are made better.

Digital Twins

Digital Twin, Modelling and Simulation in 2030

Today, a ‘digital twin’ and’ simulation’ facilitate continuous optimization for design, engineering, operation, and servicing in industrial products. Digital twins are virtual replicas of actual assets, such as a product, machine, process, or factory throughout its existence.

They contain all the information, data, descriptive, and executable models important to the administration of its real counterpart with simulation as a fundamental technology. Digital twins and simulations provide optimal design decisions and system property optimization during design and development. They assist ensure the greatest performance, utilization, and sophisticated service solutions for industrial assets.

A digital twin can accompany an industrial product throughout its existence, linking all stages of the value chain. All the data collected over a product’s lifecycle can inform its next design and use. We are just beginning to see the possibilities of digital twins and simulations, be it their tight interaction, the building of ecosystems around them, the role of AI, or developing innovative business opportunities with their support.

What to Expect

Between Strategy & Execution that surfaces evidence to Performance Management and Change.

Instances help to fuel a never-ending cycle of improvement & serve as a catalyst for change

Our Approach

Accelerate and secure Digital Twins Transformation

Praxis Value offers vast experience in content, technology, methodology, and industry in the design and development of digital twins for goods, plants, and processes. The service portfolio comprises the following issues in particular: analysis and development of business cases for digital products and process twins, vendor-independent technology selection and implementation; and descriptive, predictive, and prescriptive data analysis.

At Praxis Value we can determine the most appropriate new technologies to adopt and combine for each industry we work in. We have the capacity to conceptualize and create with our clients, to design, create, and then operate the systems they require. We can reimagine our clients’ business models, increase end-user experiences, and find new revenue streams and cost savings for them. We will speed up the intelligent industrial revolution by fusing these fields of knowledge and international expertise.

At Praxis Value we leverage facts to make impactful decisions, with the goal of maximizing financial value, and this spirit infuses all we do. Our approach is to capitalize on the potential opportunities, which results in an increase in EBITDA.

Benefits

Time-to-Market

(To Structure Design Processes)

Testing Intensity

Client Results - Case Study

Industry – Industrial Engineering

Our client was facing issues when it came to optimizing a production plant for dashboards: the entire process chain, as well as all risk elements in production and supplier management, had to become more transparent. At the same time, because a sensitive material was being processed, even minor manufacturing errors resulted in complete output rejection; the scrap rate had to be lowered

Industry 4.0 with Praxis Value

Better Productivity

Praxis Value assists industrial firms of all sizes in utilizing smart manufacturing to enhance their operational activities and production.

Improved Workflow

We provide strategies and solutions that enable you to increase productivity and value creation on your projects.

Hidden Insights

Our dedicated team of industry experts will ensure that you get the most out of Industry 4.0, the Internet of Things, and advanced analytics.

Experienced Workforce

Our firm is comprised of seasoned senior analysts from a variety of industries and data scientists skilled in advanced statistical modelling.

Related Services

What we think

What can we help you achieve?

You are on the way to the easiest business growth ever. Don’t hesitate and reach us today to change the future