Lean Production

Lean Production

Delivering Value Efficiently to the Customer

Overview

What is Lean Production?

With more companies (not just manufacturing enterprises) turning to automation to tackle daily challenges, lean production gives workers and their work dignity. Lean is an alternative to management that treats people as capital. A lean production system (pull) is based on flow and production speed that is set by the customer.

Lean Productions

Is lean manufacturing still relevant in 2021 and beyond?

Years into the COVID-19 epidemic, corporations face greater levels of uncertainty than ever before due to the unpredictability of consumer demand, the volatility of supply chains, and the instability of the broader economy. Manufacturers are tasked with predicting how things will settle into the new normal, i.e. which alterations will be long-lasting or even permanent. In such a dynamic context, some have questioned whether lean manufacturing is still relevant and valuable.

Lean has evolved to provide businesses with the optimal set of tools for navigating this new environment. The scale of the disruptions caused by the COVID-19 pandemic was unprecedented, necessitating a significant reset across all sectors of the global economy. “The companies best prepared for this reset are those utilizing Lean principles, tools, and digital operations to enhance agility and customer-centricity.

Lean Manufacturing is great for companies that want to stay on top of changes in the industrial sector, such as the introduction of new technology and the changes in the workforce that come with it.

What to Expect

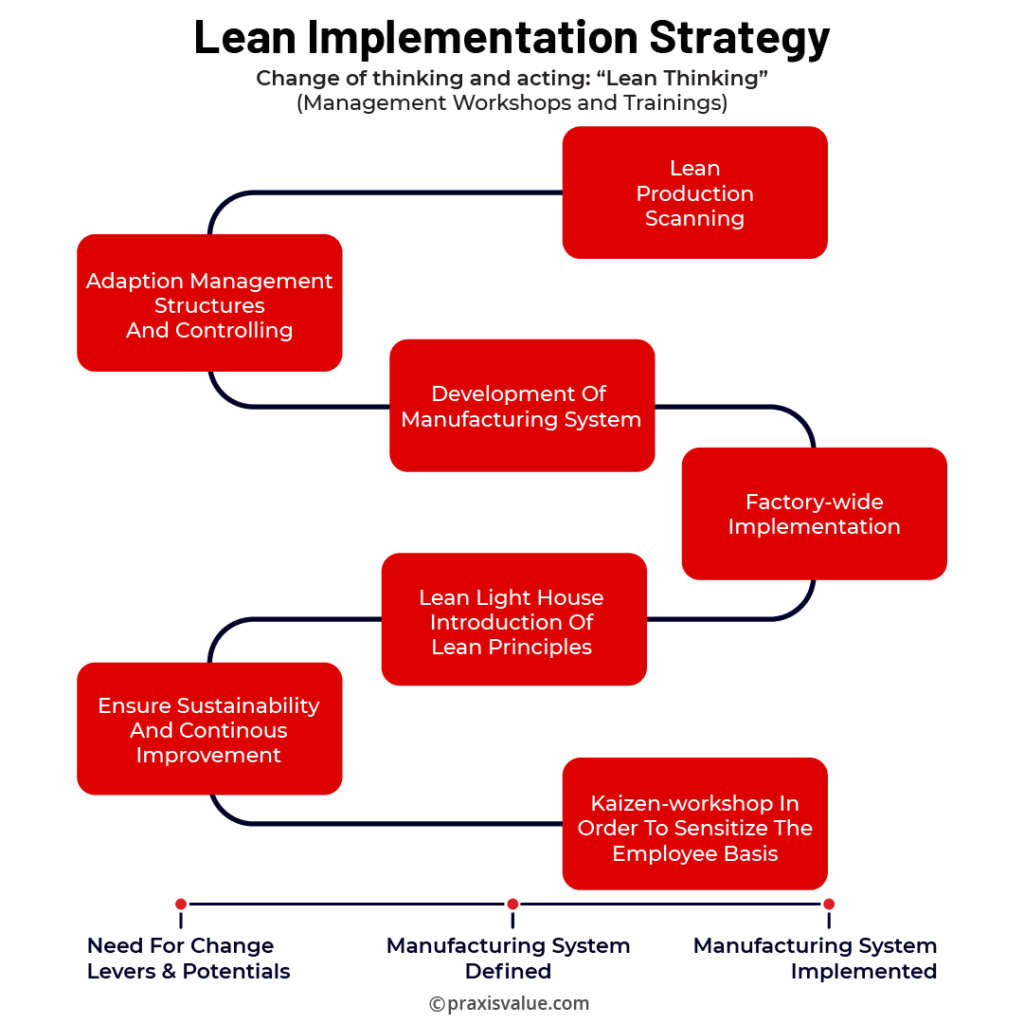

Our Approach

Transforming organizations by creating a new way of working

We transform organizations by establishing mechanisms to drive continuous improvement and engaging staff to meet client needs. Praxis Value believes lean is more than a waste-reduction “toolkit.” We build a transformation for each organization using proven methodologies for fast and deep change. Our effect comes from helping staff understand customers, monitor performance, and solve problems.

The way that businesses operate and the competitive environment in which they operate are both being disrupted on a regular basis. It’s difficult to keep up, therefore your company needs to be adaptable and quick to change, with a culture that recognizes, welcomes, and even encourages business transformation. Praxis Value’s qualified specialists and industry expertise, experience, and ability to assist organizations to identify the path ahead and create a road map that will bring them there profitably and efficiently.

At Praxis Value we leverage facts to make impactful decisions, with the goal of maximizing financial value, and this spirit infuses all we do. Our approach is to capitalize on the potential opportunities, which results in an increase in EBITDA.

Benefits

Cost of Production

Equipment Effectiveness

Overall Capacity

Client Results - Case Study

Industry – Industrial Engineering

A manufacturing was suffering from slow growth and diminished market share. To remain competitive, it needed to improve its manufacturing facilities to reduce cost and increase capacity. It also need to invest in innovation to remain competitive. Praxis Value Incorporated Lean Six Sigma principles to improve the company’s plant performance, which yielded 15 percent cost savings and increased flexibility.

Business Transformation with Praxis Value

Unlocking Value Fast

By focusing on the key areas for innovation, Capabilities & performance alignment with key enterprise strategies

Sustaining Success

By collaborating with leaders across the company to ensure that operational advantages are sustained over time

Strengthening Capabilities

By offering organizations the digital tools, skills, and expertise they need to tackle the operational challenges

Optimizing the Supply Chain

By dismantling silos and establishing transparency across the operational themeRelated Services

What we think

What can we help you achieve?

You are on the way to the easiest business growth ever. Don’t hesitate and reach us today to change the future