Digital Operations

Digital Operations

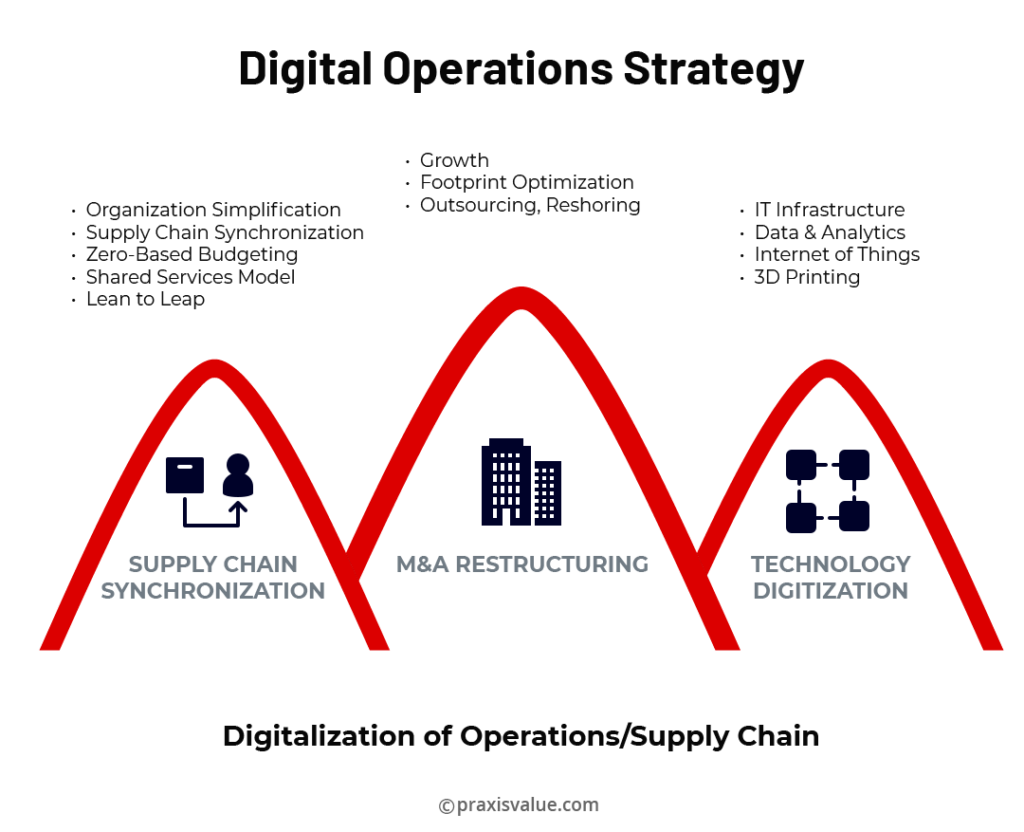

Next generation Digital Operations - Transform an Organization’s Operating Model

Overview

What is Digital Operations?

This heralds the beginning of a brand-new business discipline that will be centred on increasing the adaptability of various types of enterprises. It encompasses a comprehensive assortment of strategies and enabling technologies connected to the manner in which the organization provides value in real-time via a digital platform.

Digital Operations

The industrial digital transformation in the coming years

Taking steps toward the digitalization of manufacturing and industry, even if it means a paradigm shift, has a lot of advantages. According to a study, 86 percent of industrial companies expect to save money by implementing digital technologies in their operations.

Due to the ongoing influx of new technologies, the industrial digital transformation entails constant change. In this regard, businesses must evolve in all areas to become more flexible. In the industrial sector, efforts are being made to ensure that the use of appropriate technology reduces the time between decision-making and implementation in the plant. This cuts down on production time.

Predictive analytics helps organizations understand how their machines perform and why they stop. Predicting production failures that incur excessive expenses is conceivable. The IIoT and machine learning will help organizations save money. It’s only a matter of time before you see machines that monitor your fuel or engine. The industrial digital transformation improves productivity and performance.

What to Expect

Continuous data flow across the enterprise, phase wise smooth customer lifecycle transitions.

Ability to dive deeper into daily data in real-time allows a steadier pulse on all business areas.

Save time & money by integrating more efficient procedures & faster problem identification.

Pattern recognition, trend appraisal, data-driven opportunity boosts best practices & revenue.

Unlock efficiencies for teams, also deliver seamless, intuitive experiences for customers.

Strengthening the business infrastructure digitally , create the edge over the competition.

Our Approach

Make Industrial Digital Transformation a Reality

Praxis Value’s Digital Operations Solutions provide an agile, quick, and easy way to improve the Incident Response Lifecycle process through digital transformation and the deployment of new strategies. We help you break down data and organizational silos for operational visibility in real time, find subtle incidents in a sea of anomalies and warnings, and dynamically predict future failures.

The way that businesses operate and the competitive environment in which they operate are both being disrupted on a regular basis. It’s difficult to keep up, therefore your company needs to be adaptable and quick to change, with a culture that recognizes, welcomes, and even encourages business transformation. Praxis Value’s qualified specialists and industry expertise, experience, and ability to assist organizations to identify the path ahead and create a road map that will bring them there profitably and efficiently.

At Praxis Value we leverage facts to make impactful decisions, with the goal of maximizing financial value, and this spirit infuses all we do. Our approach is to capitalize on the potential opportunities, which results in an increase in EBITDA.

Benefits

Client Results - Case Study

Industry – Industrial Engineering

A manufacturing was suffering from slow growth and diminished market share. To remain competitive, it needed to improve its manufacturing facilities to reduce cost and increase capacity. It also need to invest in innovation to remain competitive. Praxis Value Incorporated Lean Six Sigma principles to improve the company’s plant performance, which yielded 15 percent cost savings and increased flexibility.

Business Transformation with Praxis Value

Unlocking Value Fast

By focusing on the key areas for innovation, Capabilities & performance alignment with key enterprise strategies

Sustaining Success

By collaborating with leaders across the company to ensure that operational advantages are sustained over time

Strengthening Capabilities

By offering organizations the digital tools, skills, and expertise they need to tackle the operational challenges

Optimizing the Supply Chain

By dismantling silos and establishing transparency across the operational themeRelated Services

What we think

What can we help you achieve?

You are on the way to the easiest business growth ever. Don’t hesitate and reach us today to change the future